![]() HOME

HOME

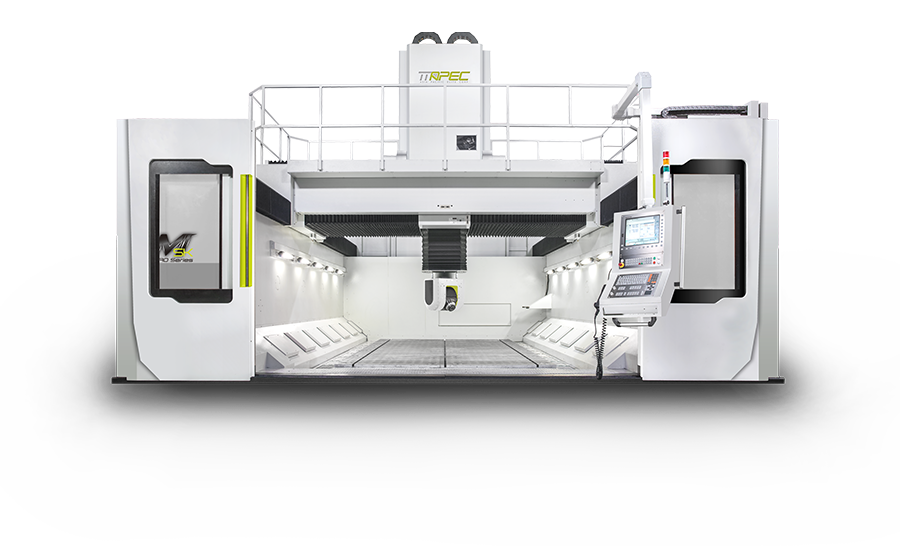

-5-axis simultaneous machining

-For aerospace aluminum machining

-Box-in-Box structure

-X/Y/Z-axis driven by linear motor

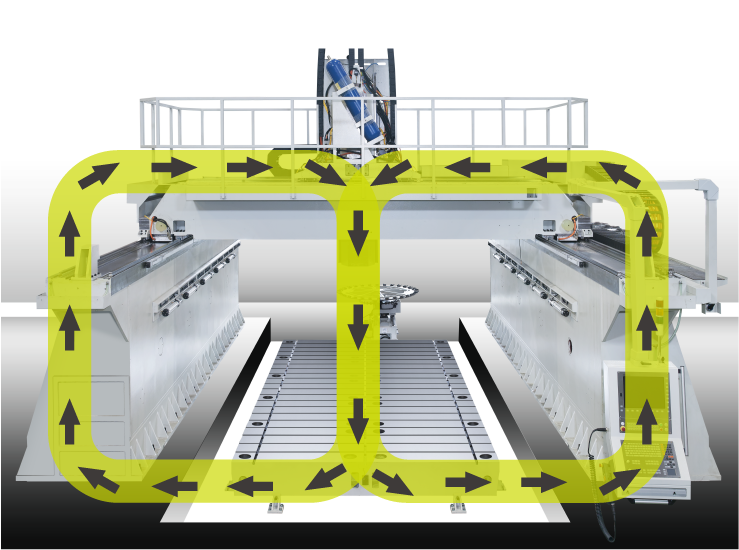

-Cross beam flushing system

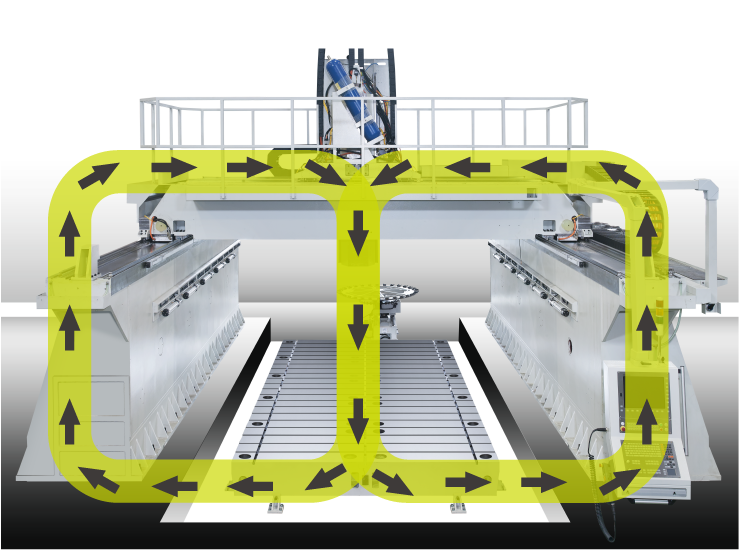

-Complex chip removal system

| Configuration |

| Box-in-Box structure Symmetrical geometry design with Box-in-Box structure of cross beam and saddle. Excellent force flow design decreases thermal deformation. High accuracy during high-speed machining can be performed. |

Unequal thickness of Ram with honeycomb structure

Ram equipped with honeycomb structure performs the best balancing design and better geometry.

Crossbeam flushing system

A high-pressure pump with groups of powerful nozzles can quickly remove the chips.

Complex chip removal system

A dual-chip removal system with a large-capacity water tank could make coolant and chip removal stable.

5-axis simultaneous machining

5-axis machining accuracy difference is below 0.01mm.

Special spindle for aluminum alloy processing

Ultra-high-speed and power spindle with the best material removal rate.

X/Y/Z-axis driven by linear motor

All three axes are driven by dual linear motors.

Max. feedrate:60 m/min

Max. acceleration:5 m/sec²

Automatic attachment head exchange system

Different angle heads could be mounted to match various applications and it is best for machining in narrow spaces.

Automatic top-roof cover

Movable beam design of top-roof cover could prevent the spreading of chips and coolant liquid.

| Specification |

| Specification | Unit | SKM2740/50/60/80 | SKM3240/50/60/80 | SKM3740/50/60/80 | |

|---|---|---|---|---|---|

| X-axis | mm | 4,000/5,000/6,000/8,000 | |||

| Y-axis | mm | 2,700 | 3,200 | 3,700 | |

| Z-axis | mm | 1,000 | |||

| Table Length | mm | 4,000/5,000/6,000/8,000 | |||

| Table Width | mm | 2,200 | 2,700 | 3,500 | |

| MAX. Table load | kg/m² | 8,000 | |||

| Rapid traverse | m /min | XYZ=60 | |||

| X.Y.Z axis acceleration | m/sec² | 5-8 | |||

| Spindle taper | HSK63A | ||||

| Spindle speed | rpm | 24,000 | |||

Spindle power ( S 1 / S6) |

kW | 60/75 | |||

Spindle torque ( S 1 / S6) |

Nm | 48/60 | |||

| Recommended 2-axis head | Fork Type Milling Head | ||||

| Swivel/Rotation Torque | Nm | B=1,192/1,980 C=1,050/1,740 |

|||

| Swivel/Rotation Speed | rpm | B=C=30(cont)/60(max) | |||

| Swivel/Rotation Angle | deg | HSK63A:B=±120° C=±360° | |||

| Clamping Torque | Nm | B=4,000 C=4,000 | |||

| Tool shank | pcs | 30T | |||

| Max. tool length | mm | 300 | |||

Max. tool diameter with adjacent tool |

mm | Ø100 | |||

Max. tool diameter without an adjacent tool |

mm | Ø130 | |||

| Weight | tons. | 52-99 | |||

- 이전글

- 이전 글이 없습니다.

- 다음글

- SK 시리즈